New opportunities for growth for high-quality 3D printed plastic products.

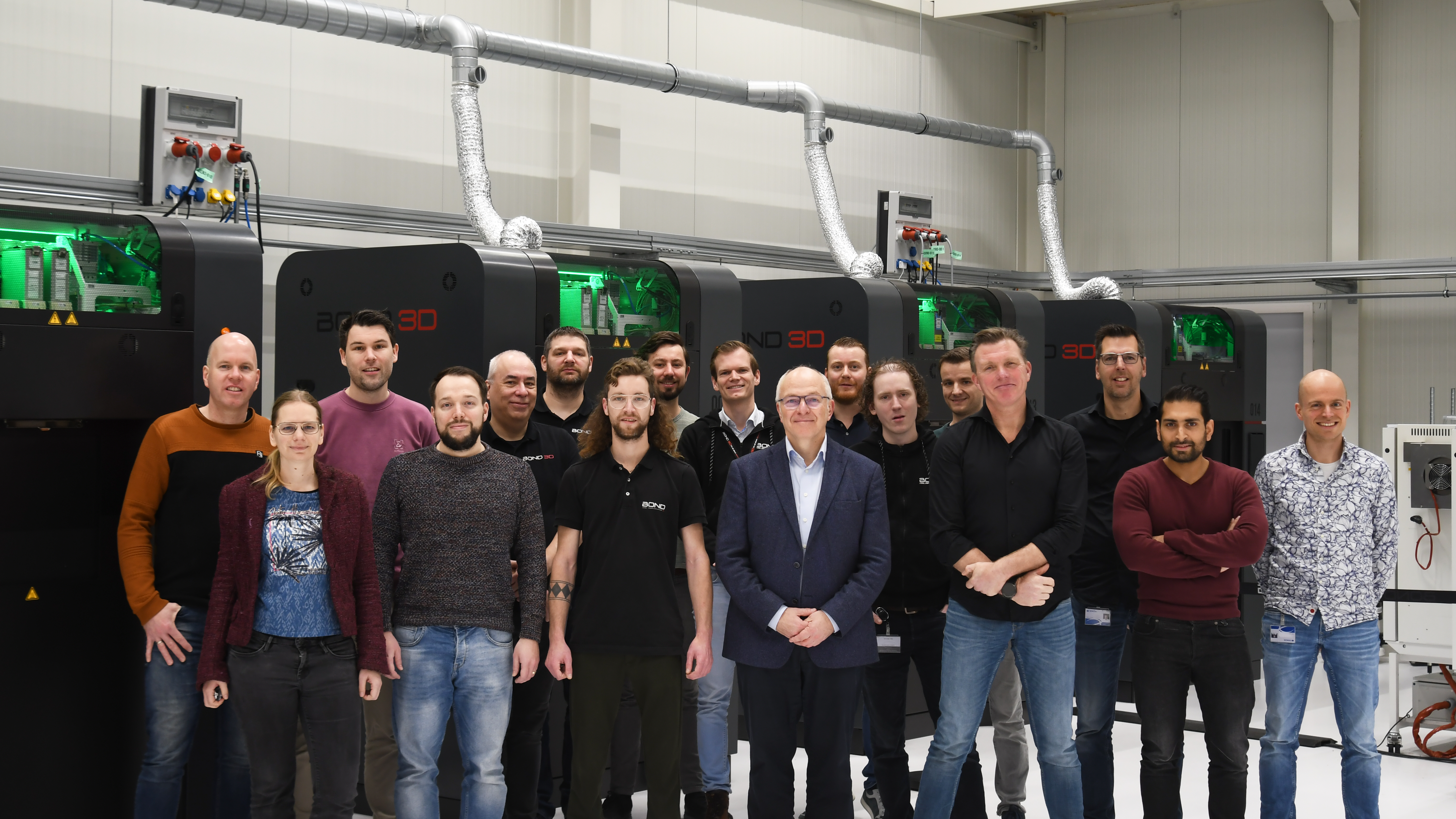

Technology developer and manufacturer Demcon acquires Bond3D. Enschede-based Bond3D develops 3D printing technology that is used to produce functional products for critical applications from high-performance plastics. Applications include medical implants and complex parts for high-tech machinery. Under Demcon’s banner, Bond3D now has greater financial clout and extensive R&D and engineering capacity at its disposal, creating new growth opportunities for the application of high-quality 3D printed plastic products. Demcon CEO Dennis Schipper hails the acquisition as a strategic move. “We can make each other stronger.”

Bond3D, founded in 2014, has succeeded in developing a technology for printing products that are 100% leak-proof, a unique achievement in the world of additive manufacturing, another word for 3D printing. Traditional 3D printing technologies have myriad advantages, including geometric freedom, minimal waste in manufacturing and its efficiency in small batches. Bond3D has been able to combine these advantages with the ability to make liquid-tight and gas-tight products.

So far, Bond3D has mainly focused its development efforts on the ultra-high-performance plastic PEEK (Polyether ether ketone), which has excellent properties in terms of mechanical strength, chemical resistance, temperature resistance and biocompatibility. Bond3D has already found applications for PEEK and its proprietary Bond3D printing technology in a variety of markets, including printed medical implants. The semiconductor industry needs strong, leak-proof and lightweight products, and Bond3D has already printed small batches for companies in the renewable energy market.

Complex medical products are notorious for their long time to market, prompting Bond3D to look for a capable and versatile technology partner with knowledge of the high-tech market and experience in medical product certification. In its quest, it approached Demcon, resulting in the decision to incorporate Bond3D into the Demcon group. The company is set to keep its name and will remain in the Demcon Technology Center in Enschede, where it took up residence four years ago.

Making each other stronger

Demcon CEO Dennis Schipper hails the acquisition as a strategic move. “We can make each other stronger. For starters, we are providing Bond3D with more financial clout, and the support of our R&D department and engineers will enable them to refine their 3D printing technology and develop new promising PEEK products. With this move, Bond3D will be able to unlock the unique properties of the material for more customers in more markets. For its part, Demcon will land in-depth knowledge of 3D printing, a relatively novel production technique that many of our high-tech customers have a keen interest in. We have already worked on metal and glass printing projects, and this acquisition puts us in a good position to improve and expand our printing expertise into engineering plastics. We have great confidence in Bond3D’s technology, due in part to our involvement in its development.” Furthermore, the acquisition will provide an influx of new colleagues who can also work on other Demcon projects. Given the close links between Bond3D and Demcon since the very beginning, it is fair to say that the circle is now complete.

About Demcon

Demcon (1,100+ employees) develops, manufactures and supplies technology and innovative products. The Demcon group has branches in Best, Delft, Enschede, Groningen, Leiden, Maastricht, Münster (Germany), Tokyo (Japan) and Singapore. The company was born out of its founders’ passion for combining creativity and technical skills to solve complex technological and social issues that directly or indirectly impact people and their environment. From medical solutions to systems that keep us safe and sustainable innovations in the realms of water and energy, Demcon’s work benefits current and future generations alike. In addition to developing technical solutions, Demcon is committed to fostering entrepreneurship and investing in talent and education.

About Bond3D

Bond3D hails from Enschede and is part of the Demcon group. Bond3D develops advanced 3D printing technology and builds 3D printers for high-performance plastics such as PEEK (Polyether ether ketone). This high-quality plastic is widely used for demanding engineering applications due to its favorable properties. The material is light, strong, chemically resistant, thermally stable and also biocompatible, which means it can be used in the human body. PEEK products printed with Bond3D technology are isotropic, which means they are equally strong in all directions, and leak-proof. They are used in the medical, semiconductor, aerospace and energy sectors, among others.