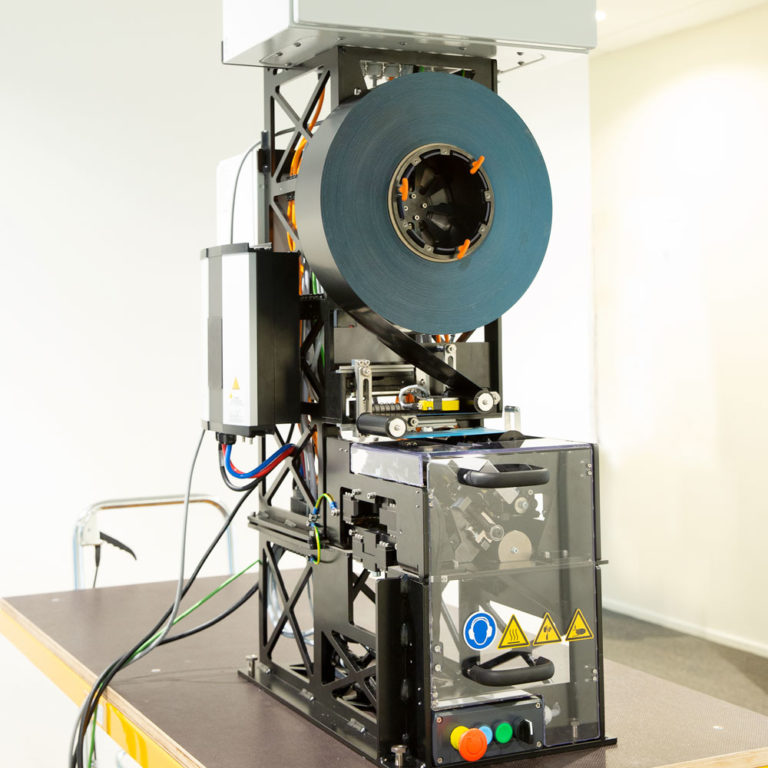

Polaroid retrofit module.

The famous Polaroid instant camera has been reborn thanks to the restart of film cartridge production in Enschede in 2008. It seemed impossible to get the old, superfast lines back up and running, but in the end it worked. Recently, we contributed with a retrofit module to further increase production.

thorough systems analysis and robust concept evaluation.

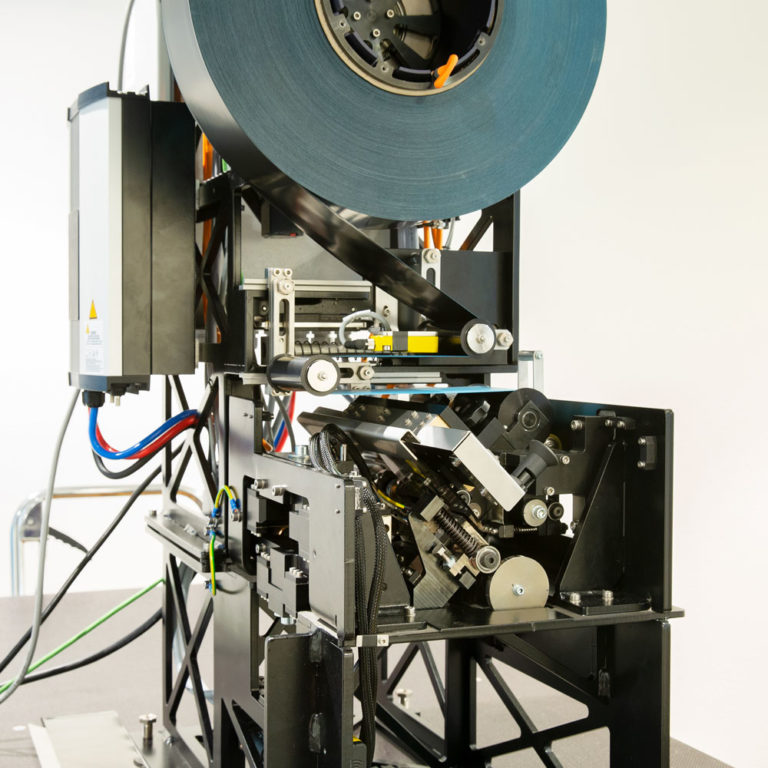

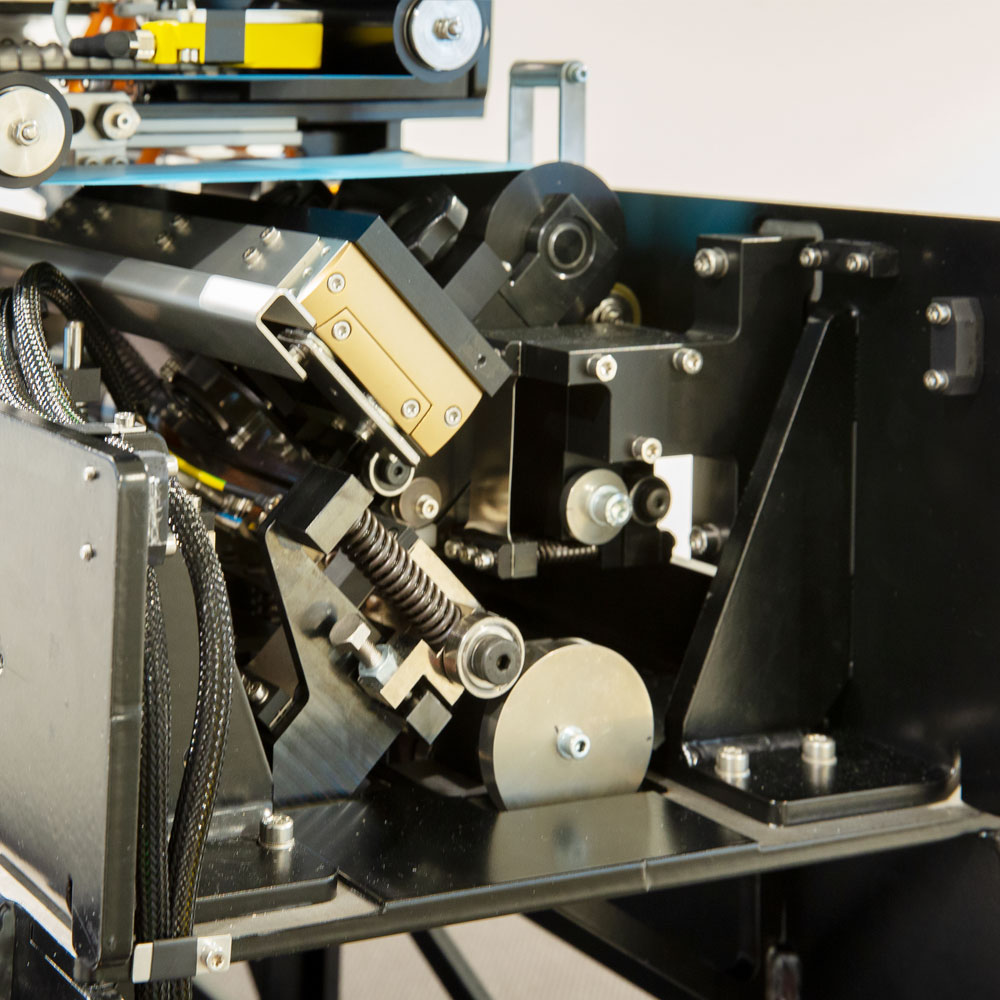

We first prepared a systems analysis together with the client to understand the problem in the current line. Next, we evaluated concepts for the three main functions: cutting, laminating and guiding. In this respect we evaluated different options in terms of various criteria such as proven technology, testability, reliability and showstoppers. The use of leaf springs and rotating technologies (bearings) ensures a long service life. An encoder on the main shaft facilitates the exact timing of the different process steps.

Erik Heijdens

Send a message“the impossible proved to be possible after all.”

Retrofit is often difficult due to limited volume budget, existing interfaces and the introduction of new production techniques. Polaroid’s rebirth had its origin as the Impossible Project. Thanks to our expertise in systems architecture, physical-chemical processes, mechatronics, system integration and industrialization the impossible proved to be possible after all. We delivered a working module within one year following our concept study.