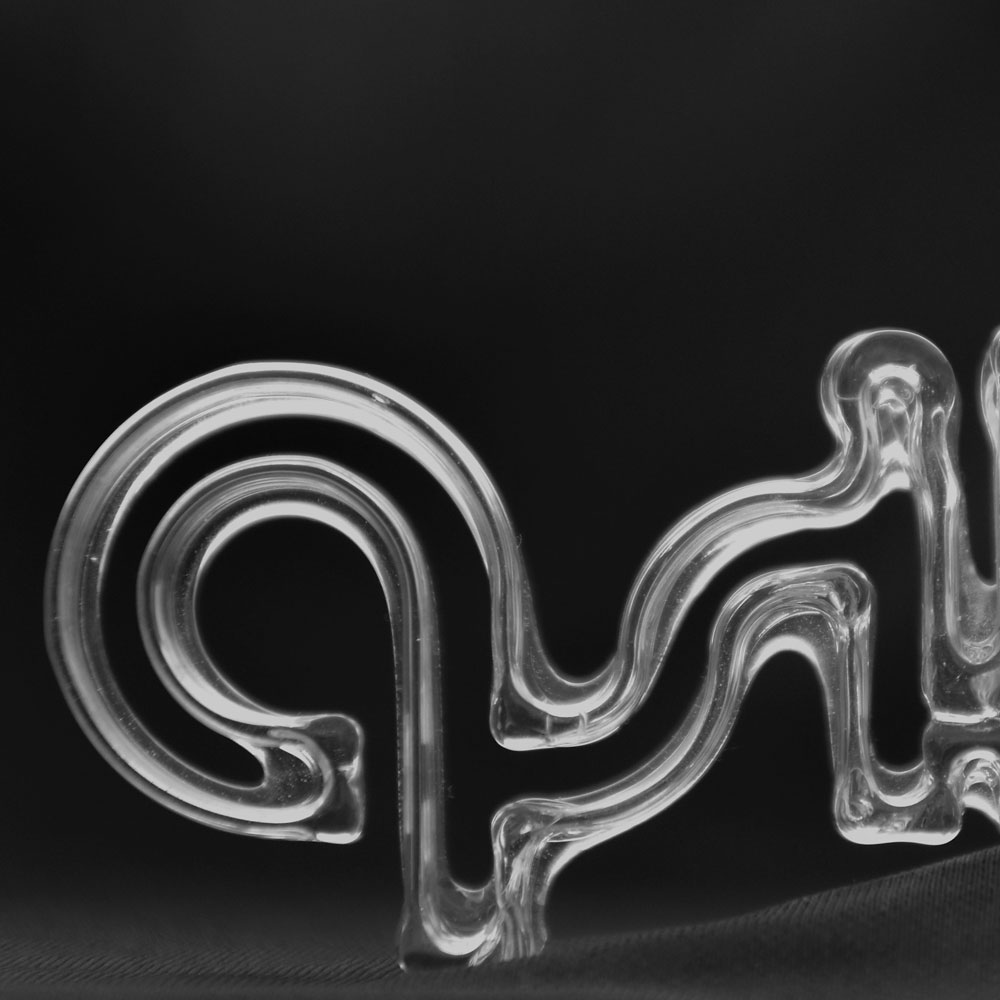

3D glass printer.

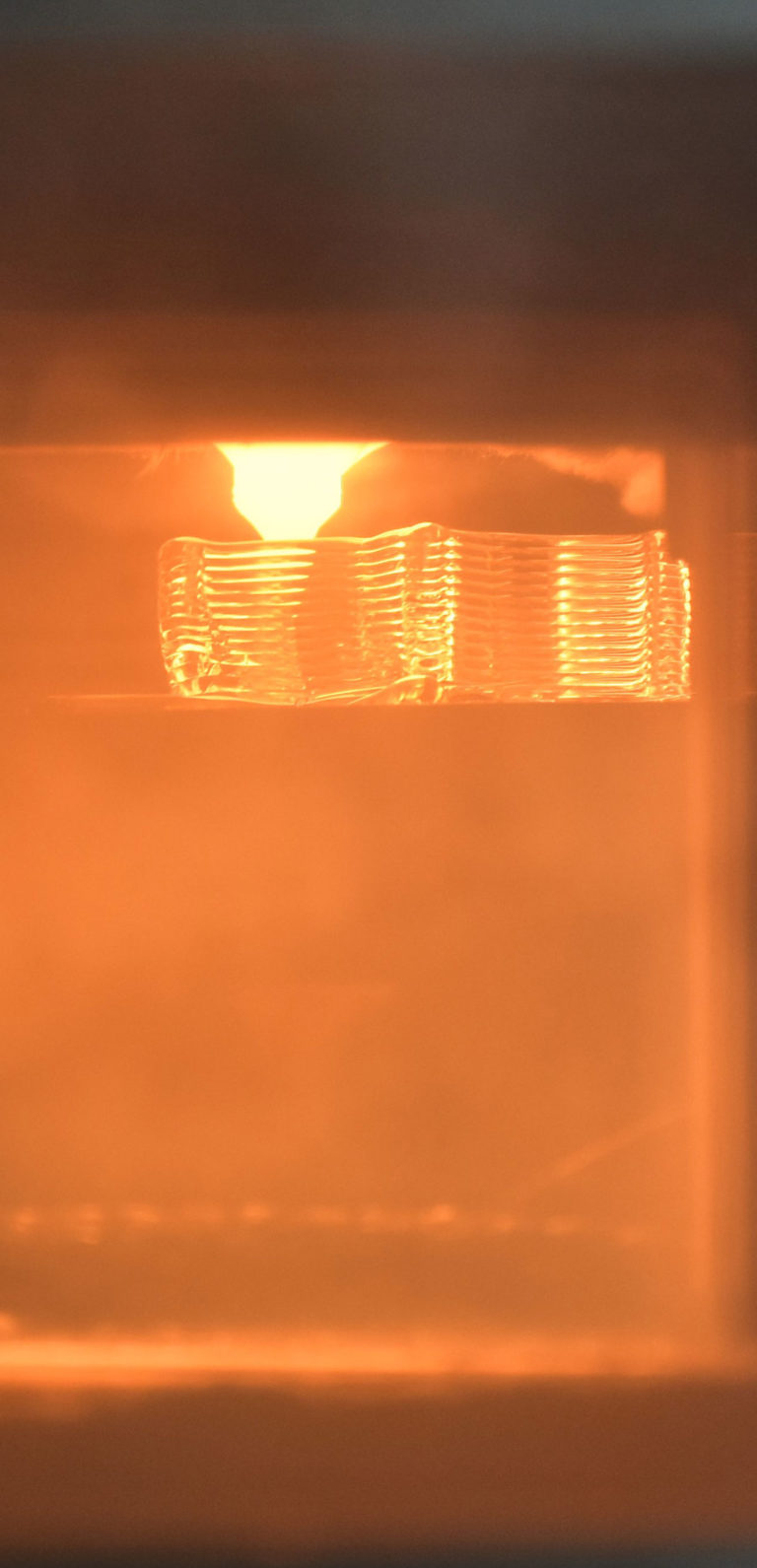

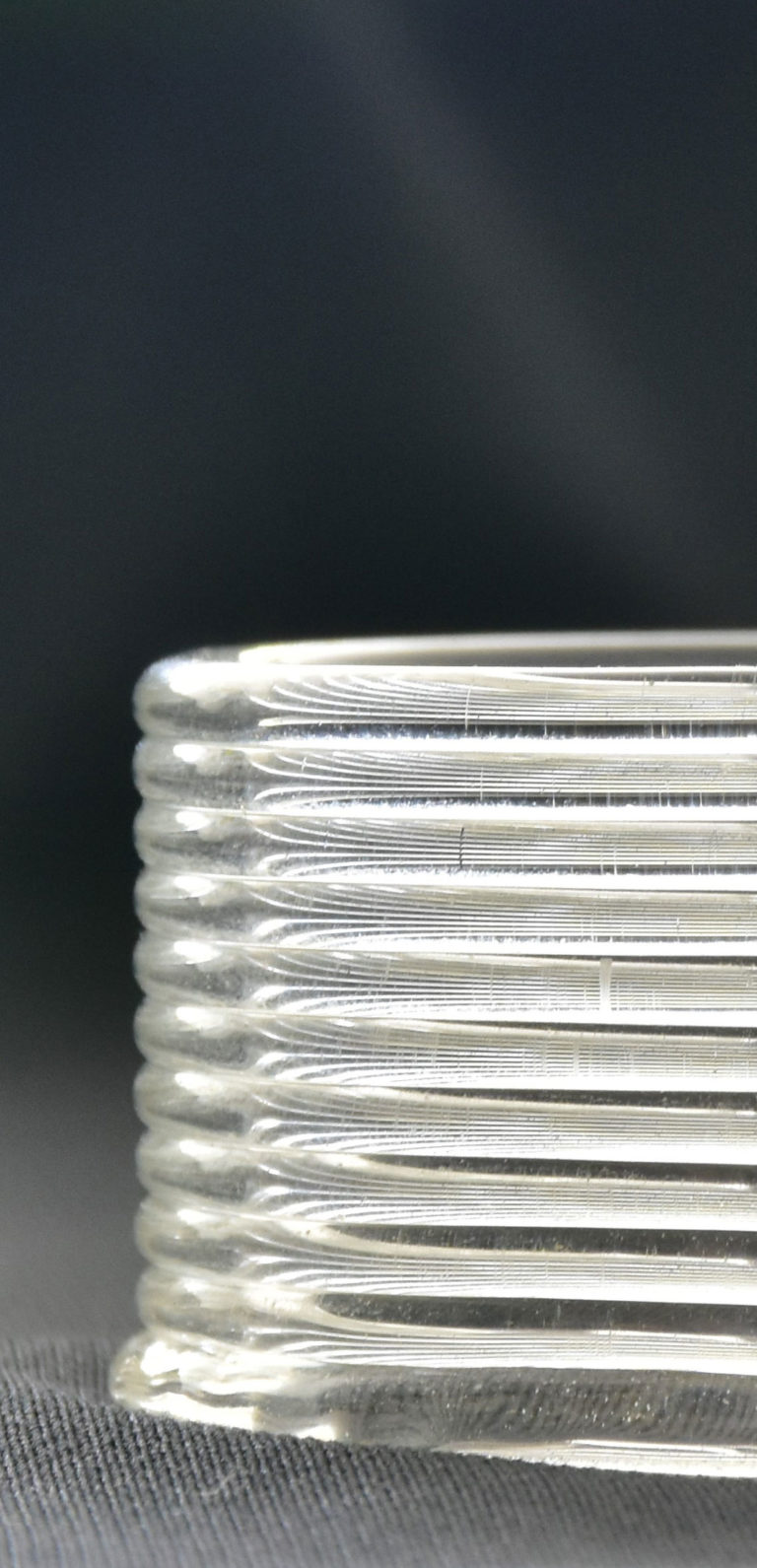

Many materials are used for 3D printing. However, glass presents a special challenge: after melting at unusually high temperatures it is viscous and after solidifying too quickly it becomes brittle. We cracked the ‘glass code’ together with QSIL and built a robust 3D glass printer for QSIL for research and demonstration purposes.

from specification to installation.

We took on the entire project, from specification to installation, using our competencies in mechatronics, thermodynamics, materials science and production. Due to the high process temperatures, controlling the temperature was an important design aspect and we had to develop advanced control and safety strategies. Thermal system simulations served to underpin the design choices in terms of hardware (materials) and software (possible compensations).

“we are one of just a few able to achieve this innovation.”

This was a typical multidisciplinary Demcon project. When it involves technologies that do not yet exist, such as 3D glass printing, we are one of just a few in the Netherlands capable of achieving such a feat. I am proud of the fact that together we have met the specifications for temperature, mechanical stability and accuracy.