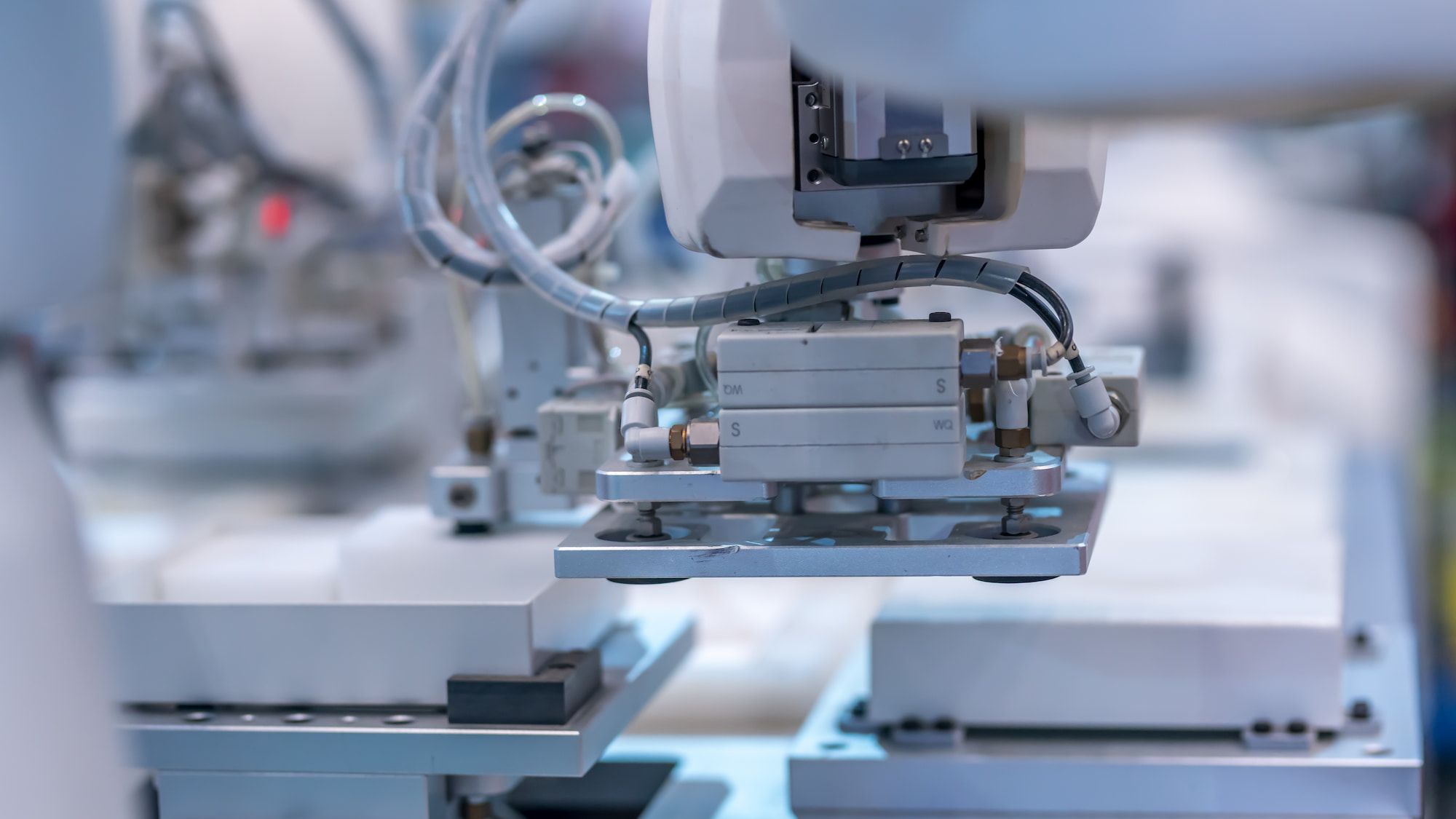

Polaroid retrofit module

Delicate materials and products, such as chips, wafers, optical fibers, films, foils and membranes require careful handling. We develop handling solutions that make full control during processing possible. They do this at high processing speeds without production losses.

High-tech products and materials are becoming increasingly thinner, more fragile and vulnerable causing processing costs to rise. This is in part attributable to miniaturization, material savings and high processing speeds. In addition, there are increasingly more special applications for delicate products; such as thin-film technology and fiber-optic communication systems. We develop efficient solutions for the controlled handling of these products at high speeds, while retaining quality. For this purpose, we draw on our extensive experience with the accurate movement and positioning, and the industrialization of continuous production processes.

Handling small, light and thin products is a special challenge. With our industrial production expertise we complement the process technological knowledge of our clients. Together we develop sophisticated designs for fast and robust processing. This way we can successfully guide vulnerable products to the market.

Additive manufacturing (3D printing) offers manufacturers unprecedented design freedom...

The scientific community is developing advanced methods for analyzing the composition...

Inspection plays an increasingly larger role in monitoring the quality of production...

Research and industry are imposing increasingly higher demands on quality control...

High-tech systems must deliver complex functionality and therefore must meet strict...

Moore’s law continues to dictate the pace of the semiconductor industry. We...

Researchers are achieving spectacular results in the laboratory with thin-film...

Thermal effects determine the quality and accuracy of numerous high-tech systems and...

Many high-tech systems use (ultra-high) vacuum to enable sensitive processes to run..