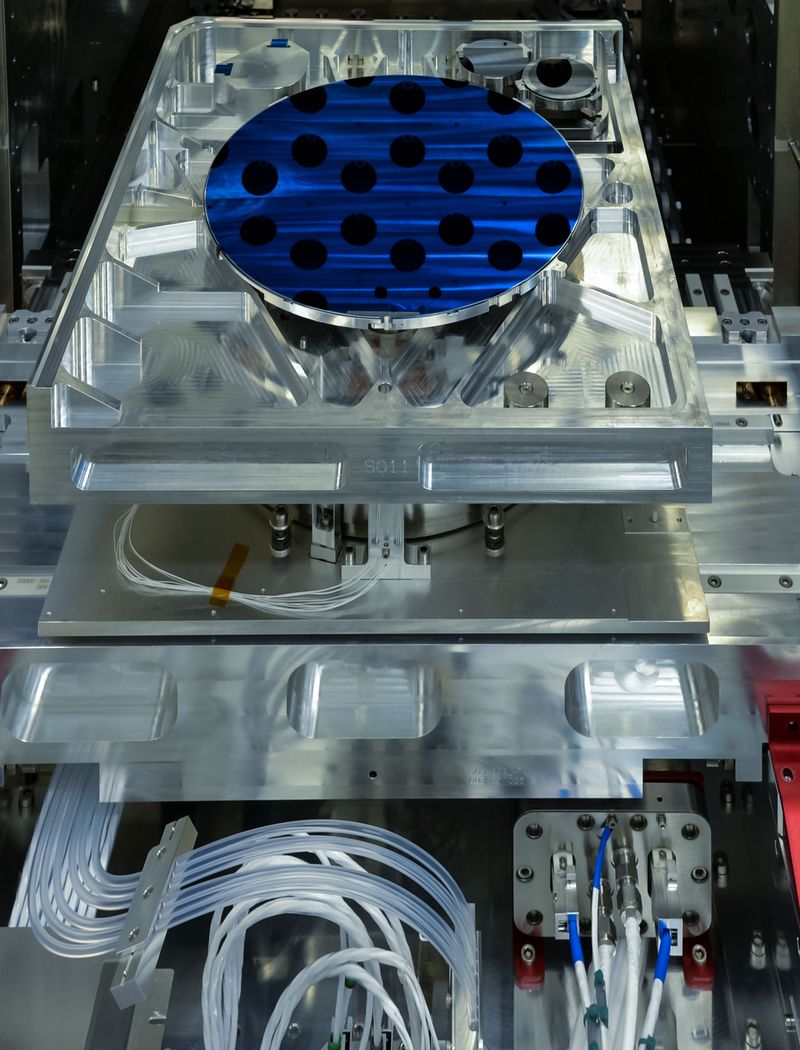

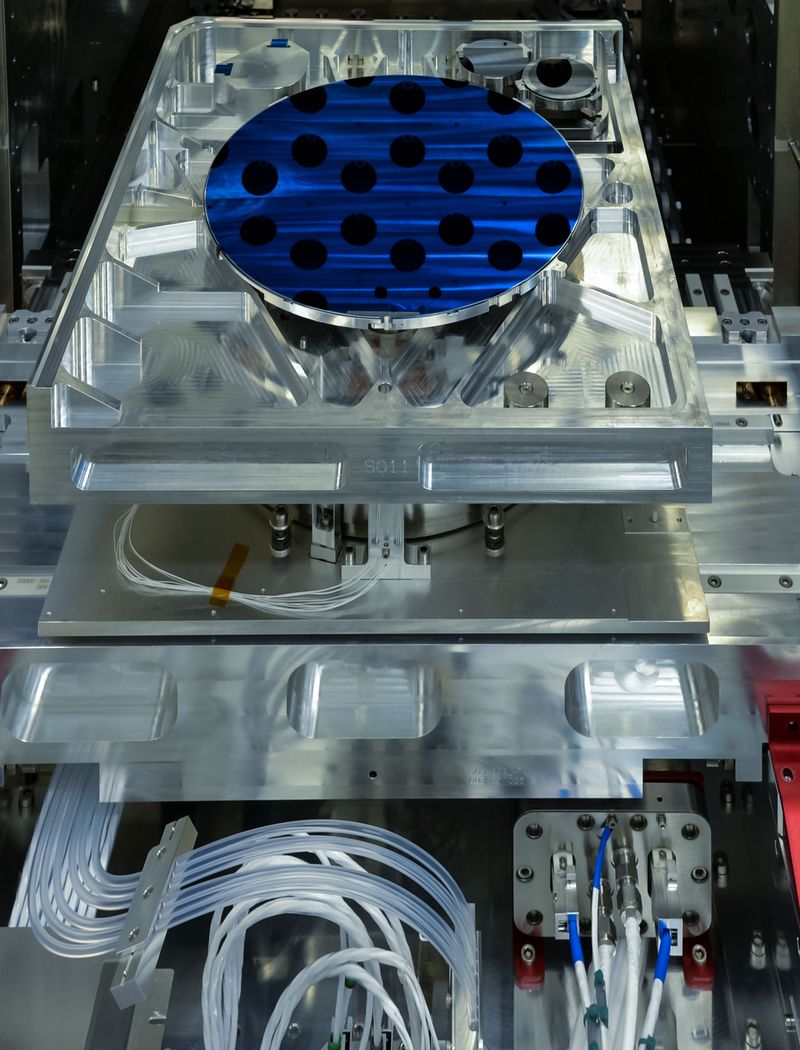

short-stroke wafer stage

Research and industry are imposing increasingly higher demands on quality control, analysis and modeling. This requires advanced metrology systems for inspecting components and their surfaces, or aligning precision systems. We develop metrological solutions for research and production, using high-quality signal processing and artificial intelligence.

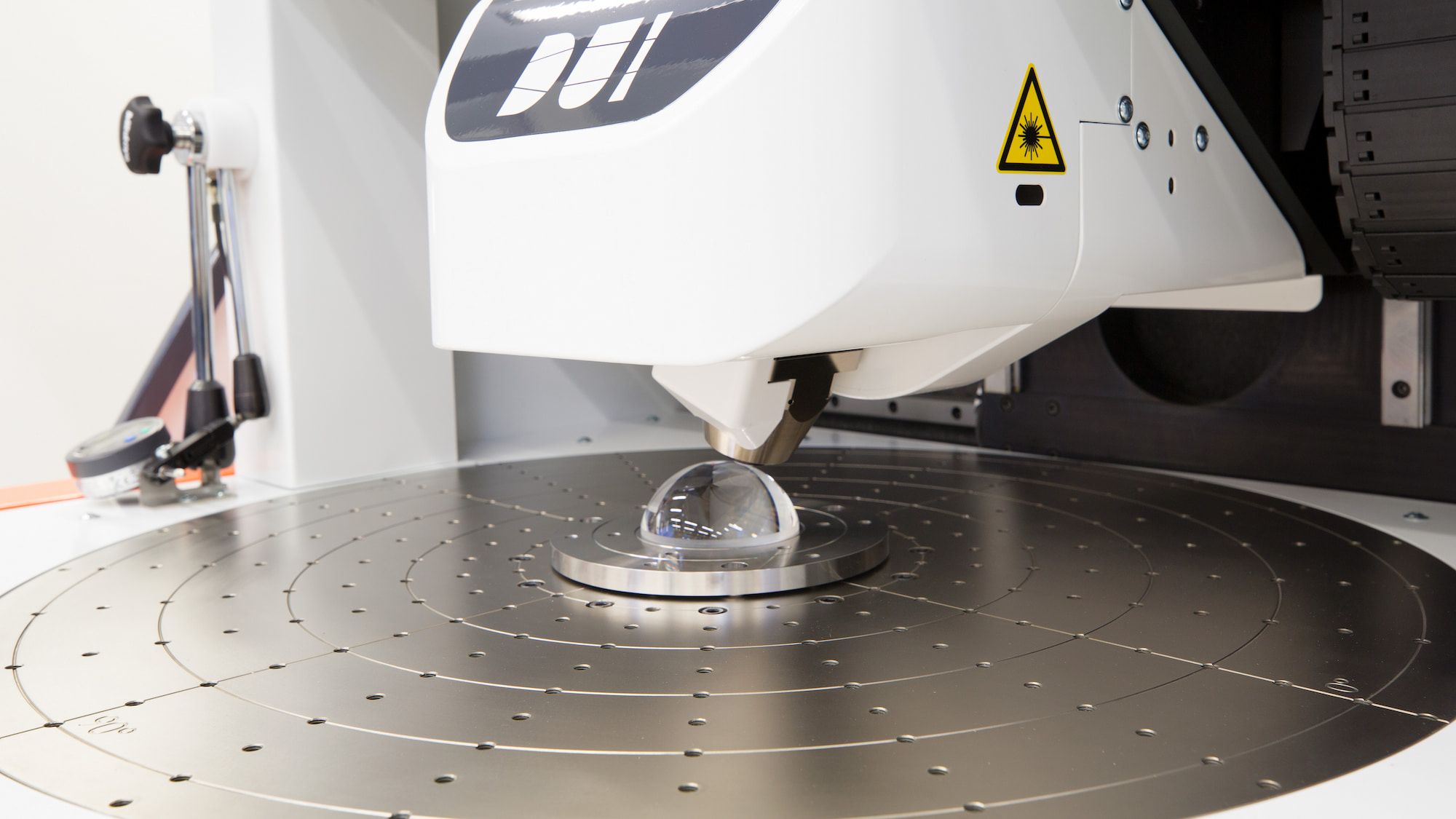

Innovations in the field of metrology provide for increasingly higher accuracy and enable optical non-contact measurements and 100% automated inspections. We develop and build metrology systems, such as measuring machines, optical scanners and automated inspection stations. We use our comprehensive expertise in mechatronics, mechanical engineering, optical metrology and artificial intelligence for this purpose. This way we are able to scan all kinds of surfaces using accurate positioning and optics. We develop smart analysis algorithms to enable us to extract maximum information from images.

We combine our expertise in the field of accurate movement and positioning with in-depth optical knowledge. This way we achieve micrometer and even nanometer precision. We do this in the laboratory, as well as in industrial practice, for example to measure free-form optical surfaces or complex semiconductor components.

Additive manufacturing (3D printing) offers manufacturers unprecedented design freedom...

Delicate materials and products, such as chips, wafers, optical fibers, films, foils...

Inspection plays an increasingly larger role in monitoring the quality of production...

The scientific community is developing advanced methods for analyzing the composition...

High-tech systems must deliver complex functionality and therefore must meet strict...

Moore’s law continues to dictate the pace of the semiconductor industry. We...

Researchers are achieving spectacular results in the laboratory with thin-film...

Thermal effects determine the quality and accuracy of numerous high-tech systems and...

Many high-tech systems use (ultra-high) vacuum to enable sensitive processes to run..