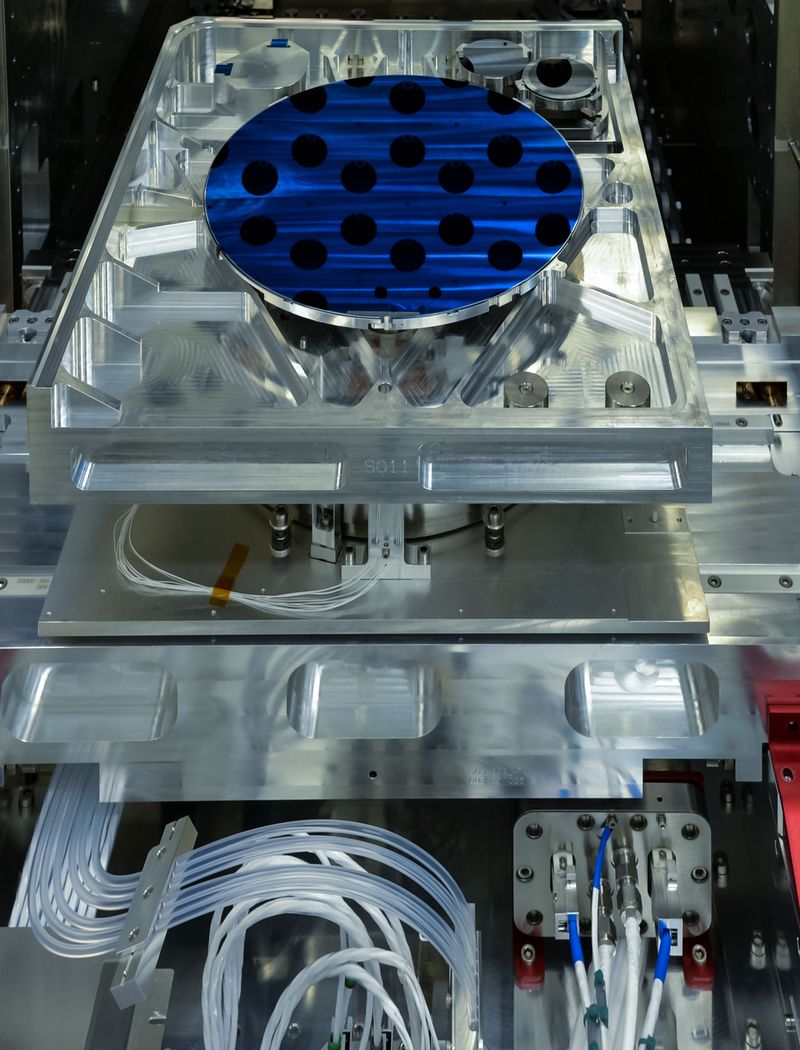

PMQT4 qualification tool

Moore’s law continues to dictate the pace of the semiconductor industry. We develop mechatronics solutions that meet challenging specifications. We serve the front-end and the back-end with modules, systems and qualification tools. We use optics, advanced simulations and data analysis to further optimize semiconductor processes.

Everything has to become smaller, faster and more accurate. In the semiconductor industry this applies to the front-end, as well as the back-end. On the basis of our broad mechatronics expertise, we develop advanced solutions for this purpose that also meet cost specifications. We deliver modules, systems and qualification tools to major OEMs and system suppliers throughout the world. Classical mechatronics no longer is sufficient to continue to be able to follow Moore’s Law. This is why we are deploying additional technologies, such as optics and simulations. Data analysis helps us realize better products and services even faster.

The semiconductor industry is part of our DNA. At the front-end we use all of our mechatronics competencies in order to comply with the extreme specifications. We combine that experience with our industrialization expertise to build efficient systems for the back-end. In every instance, for the front-end and for the back-end, with the highest quality and maximum cost control.

Additive manufacturing (3D printing) offers manufacturers unprecedented design freedom...

Delicate materials and products, such as chips, wafers, optical fibers, films, foils...

Inspection plays an increasingly larger role in monitoring the quality of production...

Research and industry are imposing increasingly higher demands on quality control...

High-tech systems must deliver complex functionality and therefore must meet strict...

The scientific community is developing advanced methods for analyzing the composition...

Researchers are achieving spectacular results in the laboratory with thin-film...

Thermal effects determine the quality and accuracy of numerous high-tech systems and...

Many high-tech systems use (ultra-high) vacuum to enable sensitive processes to run..